1 / 3

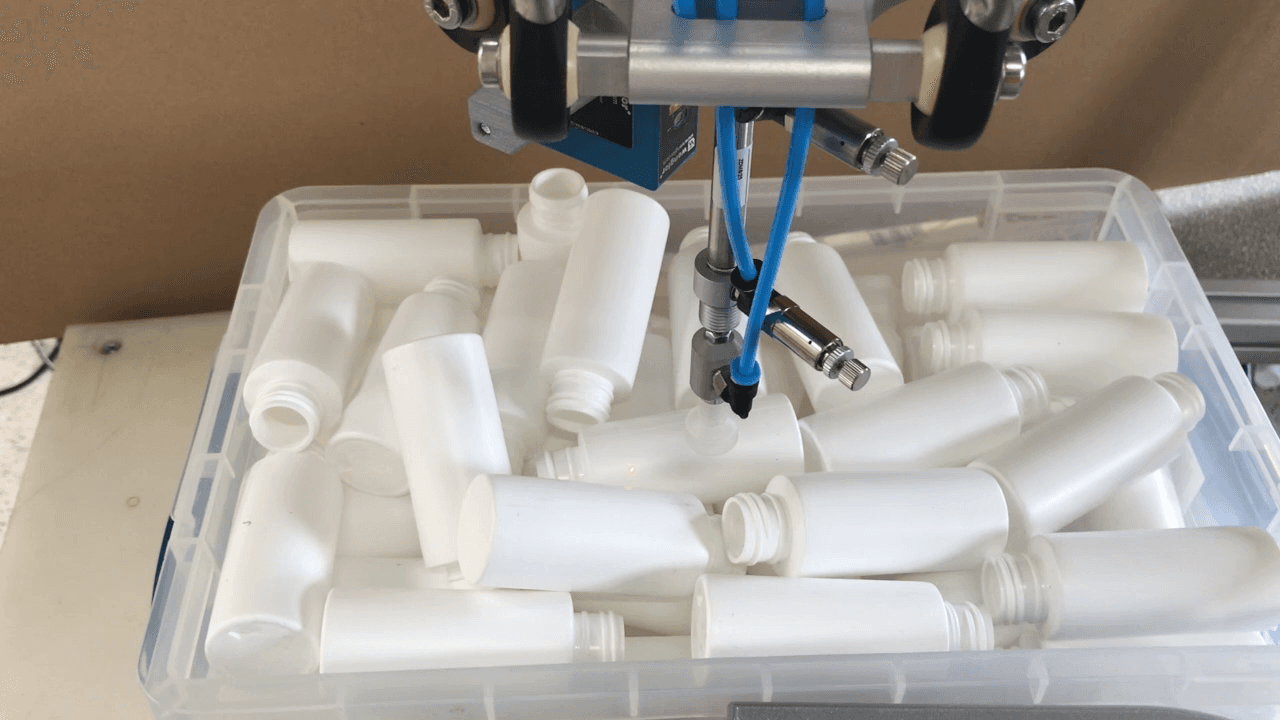

1 / 3DOBOT CR5 with 3D vision demonstrates bin picking of flanges

Cena hardvéru:

DOF

6

Repeatability

0.02

mm

Max. reach

900

mm

Intelligent Bin Picking of Flanges with DOBOT CR5 and 3D Vision

The DOBOT CR5 collaborative robot, equipped with advanced 3D vision technology, enables efficient and precise bin picking of flanges from randomly arranged setups. The vision system accurately identifies and localizes each flange, while the robot picks and places the components in a defined orientation for subsequent processing with reliability and precision. By automating the handling of complex geometries, this solution reduces manual labor, enhances efficiency, and ensures flexibility, making it ideal for manufacturing environments requiring intelligent part sorting.

What is the Application?

The system automates bin picking and part orientation, optimizing workflows for industries like automotive, machinery, and general manufacturing.

What are the Advantages of the Solution?

Advanced 3D Vision: Identifies and localizes components with high accuracy.

Efficient Workflows: Reduces manual sorting, saving time and labor costs.

Flexible Handling: Adapts to complex shapes and diverse setups.

What are the Advantages of the Robot?

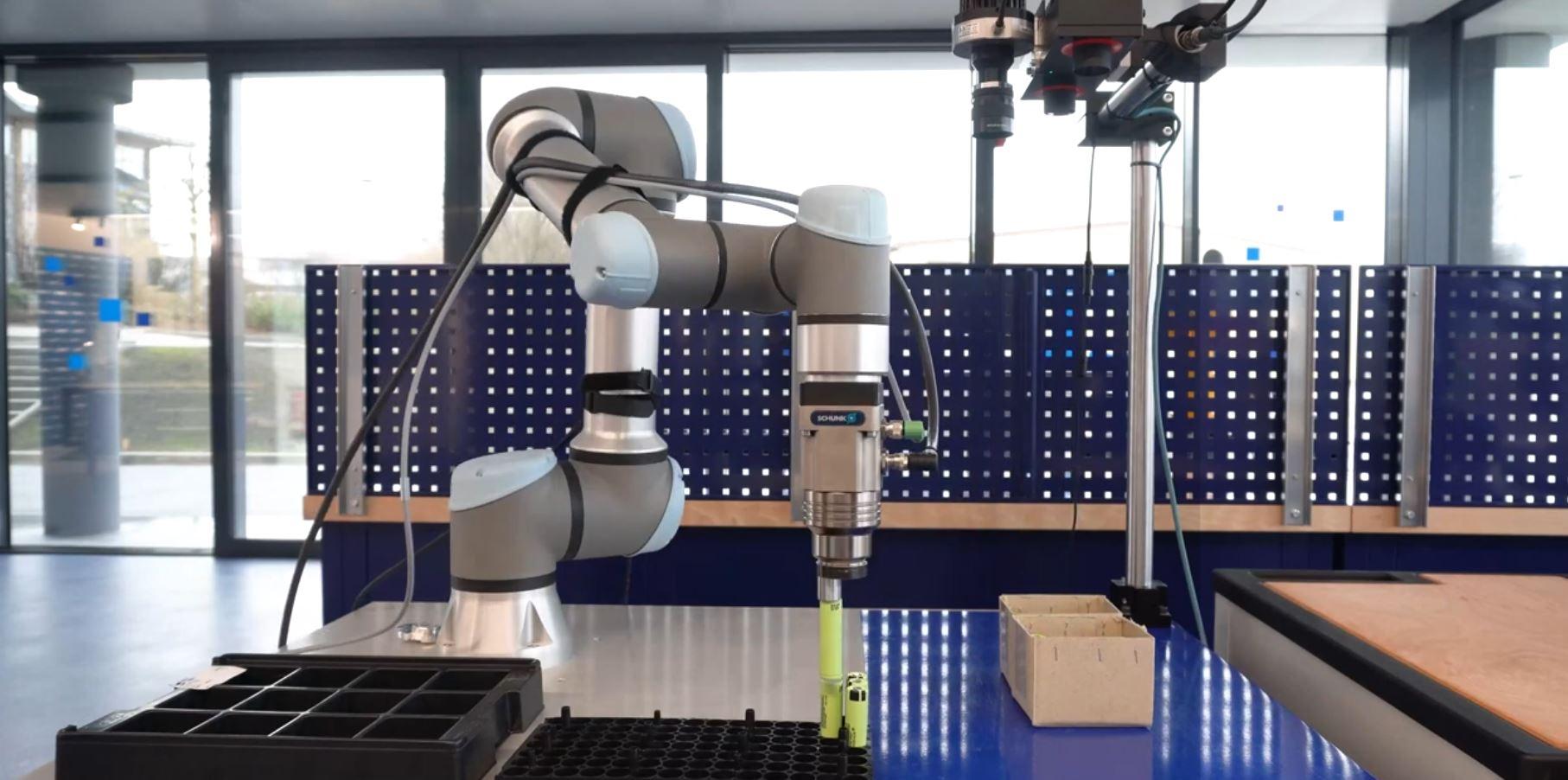

The DOBOT CR5 excels in intelligent bin picking tasks:

High Precision: Reliable picking ensures accurate positioning for further processes.

Compact Design: Seamlessly integrates into production lines.

Scalable Operation: Handles varying part sizes and configurations with ease.

Optimizing Flexible Part Handling with DOBOT CR5

The DOBOT CR5 with 3D Vision delivers an intelligent and efficient solution for bin picking in demanding manufacturing environments. By automating complex handling tasks, it ensures precision, reduces manual efforts, and supports flexible workflows to improve productivity and process reliability.

2 Components